What is Hot Stage Microscopy?

Linkam TS1500 Hot stage at 1500 °C

Hot stage microscopy is a powerful analytical technique that allows researchers to investigate the properties of materials at high temperatures, in real-time and under controlled conditions. It has a wide range of applications, from materials science and chemistry to food science and pharmaceuticals. In this article, we will explore the benefits of hot stage microscopy and how Linkam's product range can help researchers in these fields.

A wide range of materials, including polymers, metals, ceramics, and biological samples can be analysed using hot stage microscopy making it a highly versatile technique. By heating the sample to a specific temperature, researchers can induce various thermal phenomena such as melting, crystallisation, and phase transitions, which can provide important information about the sample's properties.

Linkam's hot stage systems are renowned for their exceptional temperature control, which is the result of over 40 years of experience in developing and refining our product range. Our systems offer precise and accurate temperature control for a range of sample types and sizes, with different stages capable of operating between < -195 to 1500 °C. This level of control ensures that researchers can achieve reliable and reproducible results. They are also compatible with a variety of analytical techniques, including Raman spectroscopy, FTIR spectroscopy, X-ray diffraction and fluorescence spectroscopy. This enables researchers to gain more insight into the structural and chemical changes that occur in the sample during heating.

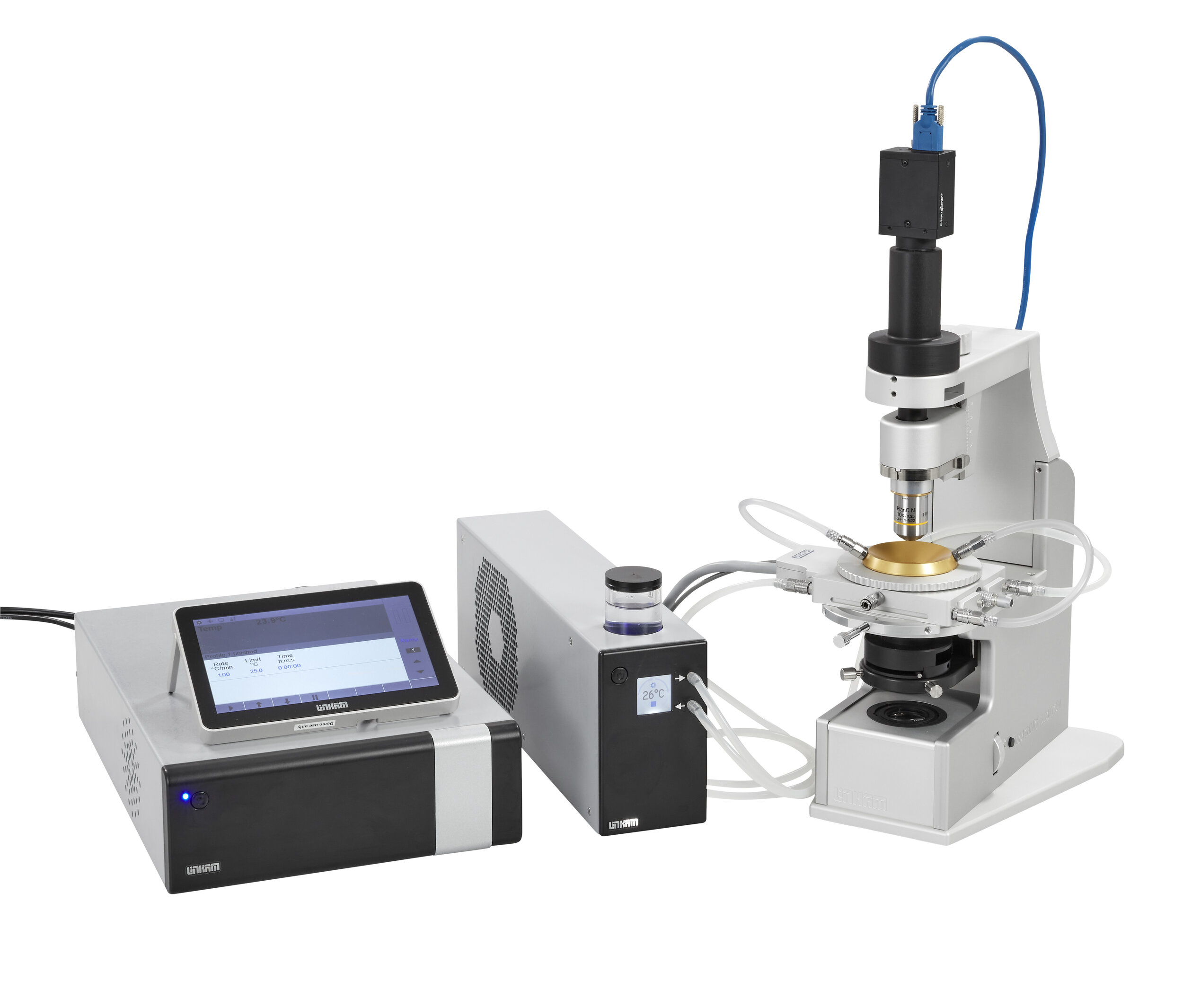

Complete Linkam Hot Stage Microscopy System consisting of a TS1500 High Temperature Stage, Imaging Station and WCP Water Circulation Pump

applications of Hot Stage Microscopy?

Melting Behaviour

Hot stage microscopy can be used to study the melting behaviour of polymers, which is crucial for determining their processing conditions and applications [1]. As the polymer is heated, its crystalline structure begins to break down, resulting in a change in its optical and mechanical properties. Hot stage microscopy allows researchers to observe this behaviour in real-time, enabling them to determine the melting temperature and analyse the sample's crystalline structure as it undergoes the transition from solid to liquid. Combining hot stage microscopy with differential scanning calorimetry (DSC) is another powerful technique used to study the melting behaviour of polymers. Linkam's DSC450 stage provides simultaneous thermal and microscopic analysis. By combining the high sensitivity of DSC with the visual capabilities of hot stage microscopy, researchers can obtain a more comprehensive understanding of the thermal properties of polymers and other materials.

Crystallisation

Hot stage microscopy can also be used to study the crystallisation behaviour of a material [2]. As the sample is cooled from its molten state, its structure begins to reorganise into a crystalline form. Hot stage microscopy enables researchers to observe this process, providing information about the size, shape, and orientation of the crystals that form. This can be particularly useful in fields such as materials science and metallurgy, where the properties of a material are closely linked to its crystalline structure. However, when cooling it is important to be aware of supercooling which can delay the onset of crystallisation to temperatures significantly below the melting point of a material.

Catalysis

Hot stage microscopy can also be used to study the interaction between a catalyst and a reactant during a chemical reaction [3]. By heating the sample and introducing a reactant gas, researchers can observe the behaviour of the catalyst and the products that are formed.

This provides important information about the mechanism of the reaction, the role of the catalyst, and the selectivity of the products. For example, hot stage microscopy can be used to study the sintering behaviour of catalyst particles; the process of particles fusing together due to heat.

Sintering can significantly reduce the activity of a catalyst, so understanding how it occurs is crucial for designing more stable and efficient catalysts. Hot stage microscopy allows researchers to observe the sintering process in real-time and study how it is influenced by factors such as temperature, pressure, and gas atmosphere.

Electrical Measurements

In addition to studying the thermal behaviour of samples, hot stage microscopy can also be used in conjunction with electrical measurements to investigate the electrical properties of materials at high temperatures [4]. This technique is known as electrical measurement testing and involves simultaneously measuring the electrical properties of a sample while it is heated or cooled.

Electrical measurement testing is particularly useful in fields such as materials science, where the electrical properties of materials play a crucial role in their performance. For example, electrical conductivity is an important property in many applications, including semiconductors, batteries, and fuel cells. By combining hot stage microscopy with electrical measurements, researchers can study the changes in electrical conductivity as a function of temperature, providing insights into the mechanism of conduction and the properties of the material.

Hot stage microscopy is a powerful analytical technique that offers a wealth of information about the behaviour of materials under controlled heating conditions. Linkam's hot stage microscopy systems provides researchers with precise temperature control, compatibility with a variety of analytical techniques, and high-resolution imaging capabilities, making it an invaluable tool for materials science [5], chemistry[6], and several other fields including pharmaceuticals [7], life sciences [8] and geology [9]. By choosing Linkam's hot stage microscopy equipment, researchers can achieve high-quality results and gain a deeper understanding of the behaviour of materials at high temperatures.

Sign up to Linkam Newsletter

Sign up to receive regular updates on Linkam products, and the innovative research being carried out with them.

References

[1] Ashton, G.P., Charsley, E.L., Harding, L.P. et al., “Applications of

a simultaneous differential scanning calorimetry–thermomicroscopy

system”, J. Therm. Anal. Calorim., 147, 1345–1353 (2022)

DOI: 10.1007/s10973-020-10514-3

[2] Lopez-Quiroga, E., Wang, R., Gouseti, O. et al., Crystallisation in concentrated systems: A modelling approach, Food Bioprod. Process., 100, 525-534 (2016)

DOI: 10.1016/j.fbp.2016.07.007

[3] Jaworska, L., Szutkowska, M., Klimczyk, P. et al., “Oxidation, graphitization and thermal resistance of PCD materials with the various bonding phases of up to 800 °C”, Int. J. Refract. Hard Met., 45, 109-116 (2014)

DOI: 10.1016/j.ijrmhm.2014.04.003

[4] Linkam White Paper: Achieving precise temperature control in semiconductor and electronics research

[5] Wang, J., Zhang, A., Wang, Q. et al., “Integrated a Fused Silica Capillary Cell and In Situ Raman Spectroscopy for Determining the Solubility of CO₂ in n-Decane and n-Decane + n-Hexane System”, Processes, 11, 1137 (2023)

DOI: 10.3390/pr11041137

[6] Warren, M.R., Brayshaw, S.K., Johnson A.L. et al., “Reversible 100 % Linkage Isomerization in a Single-Crystal to Single-Crystal Transformation: Photocrystallographic Identification of the Metastable [Ni(dppe)(η₁-ONO)Cl] Isomer”, Angew. Chem., 48, 5711-5714 (2009)

DOI: 10.1002/anie.200901706

[7] Kumar, A., Singh, P. & Nanda, A., “Hot stage microscopy and its applications in pharmaceutical characterization”, Appl. microsc., 50, 12 (2020)

DOI: 10.1186/s42649-020-00032-9

[8] Linkam Case Study: Temperature-controlled microscopy enhances research of chemical processes in polar ice

[9] Linkam Application Note: Investigating fluid inclusions to understand ore forming processes and for sequestration of carbon dioxide