Mechanical Testing

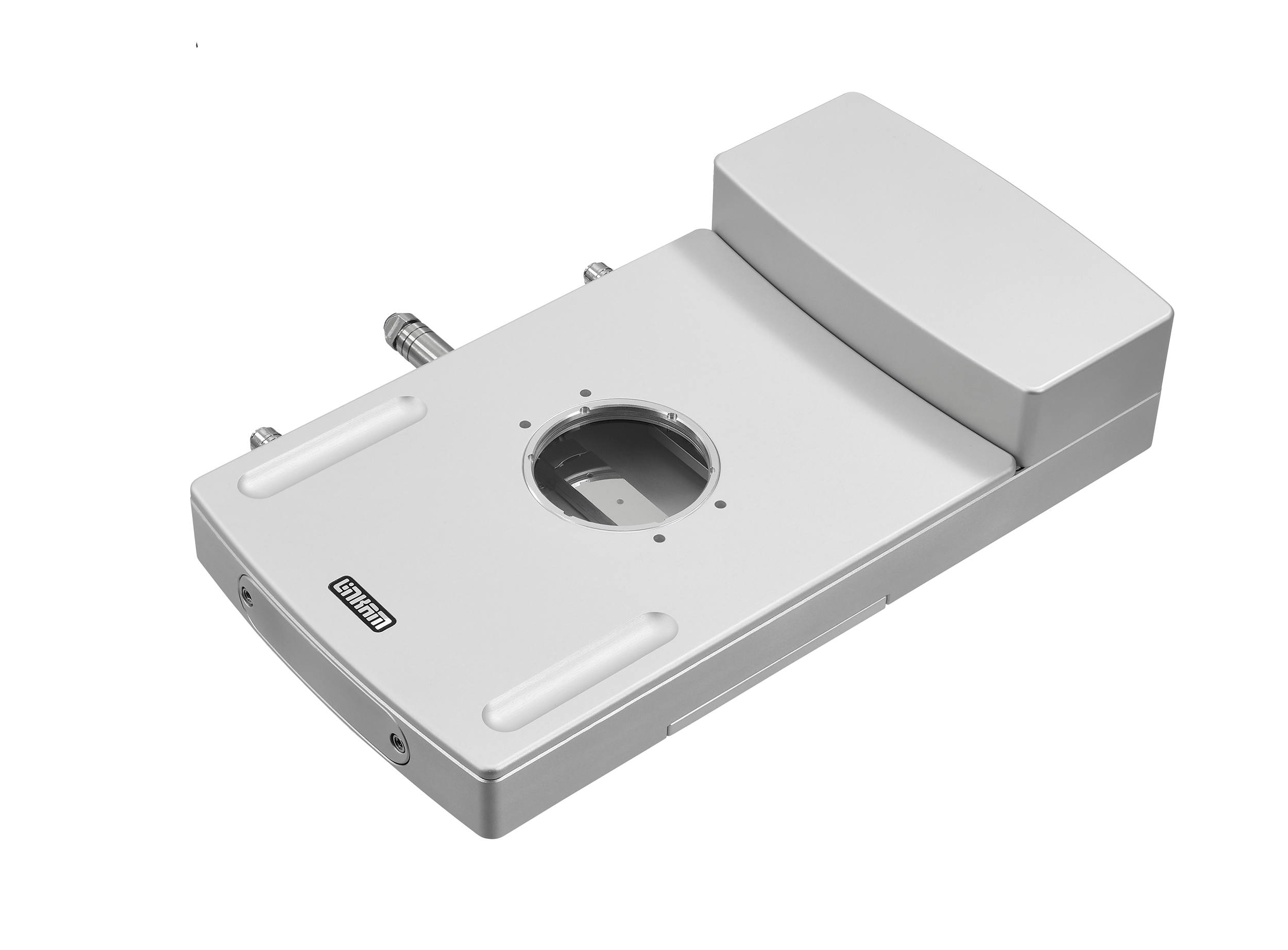

MFS - Modular Force Stage

Mechanical sample characterisation with temperature and environmental control modules.

Read about research using Linkam’s mechanical testing systems:

With increased pressure on the electronics sector to deliver greener technology with uncompromised performance, materials research and development has stepped up to the fore.

The understanding of microscopic and thermo-mechanical properties is at the core of materials science research. Here we look at how mechanical characterisation can be used to observe and image materials at the microscale.

Researchers at Reading Scientific Services Ltd. (RSSL) performed tensile testing on both chicken and plant-based chicken alternative samples.

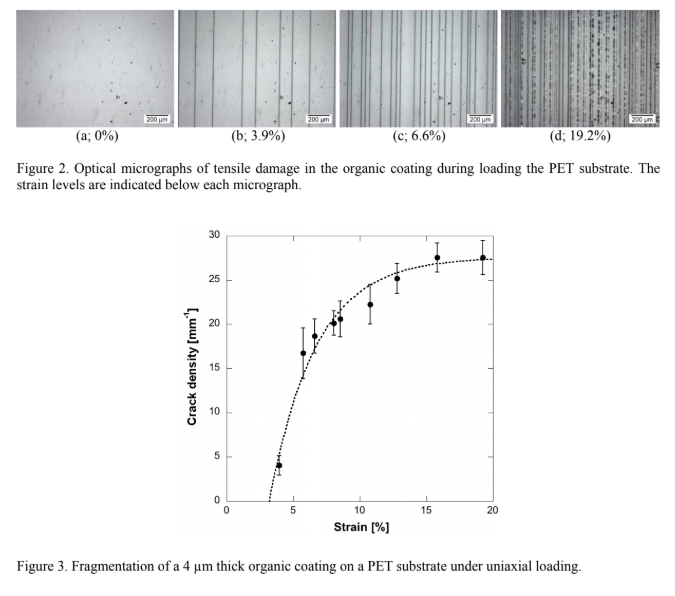

Linkam’s mechanical testing system was used to study the mechanical integrity and adhesive properties of polymer coatings.

Researchers at the University of Bath develop understanding of novel materials with single-walled carbon nanotubes using Linkam’s tensile stages.

Researchers at the National Chemical Laboratory, India, explain how Linkam’s TST350 (now MFS) can be used to calculate the essential work of fracture for polymeric materials.

Researchers use Linkam’s TST350 (now replaced by the updated MFS) to study biomaterials for corneal replacement.

Researchers in Lausanne use Linkam’s mechanical testing system to study the effect of temperature on the adhesion of transparent thin film electrodes on polymers.

Researchers use the Linkam MFS to image and measure the tensile properties of nanocomposite samples synthesised by coagulation spinning using carbon nanotubes.

Linkam’s mechanical testing stage was used to study the tensile properties of ITO-free flexible electrodes, used for optoelectronic devices, revealing their mechanical integrity under bending and stretching conditions.

Using one of Linkam’s mechanical testing stages, researchers at Imperial College London look at tenile properties of carbon nanotube reinforced composite fibres.

NEED MORE INFORMATION?

Complete the form below and one of our technical experts will be in touch shortly.

The remarkable functional properties of spider silk make it a highly interesting material for a wide range of applications, including high-performance fabrics and regenerative medicine.