CSS450 Stage Support

This section contains support specific to the CSS450 stage. If your question isn’t listed here it could be covered under the ‘General Stage Support’ page.

CSS450 Shear stage displaying an 'open circuit' error message

If your CSS450 Shear system is displaying the error message 'Stage temperature sensor open circuit or over range', the lid may not be correctly connected.

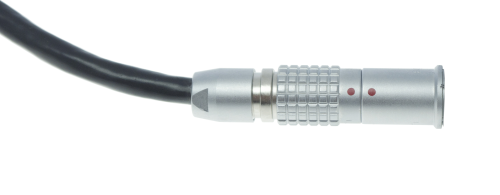

The lid Lemo connector must be connected to the stage base, with the red dots on the connectors lined up as shown below:

If this does not resolve your issue, please refer to the following advice: System displaying an 'Open Circuit' or 'Temp Overrange' message

Lid seems stuck

If the gap motor cannot raise/lower the lid, it is possible that the sample may have set solid between the shear windows. By melting the sample, it may be possible to separate them, and this should be tried first. In the event that this does not work, the following procedure should be used to force the lid away from the stage body. This procedure will almost certainly damage one or both of the windows. Make sure you have the appropriate spare windows before starting this procedure.

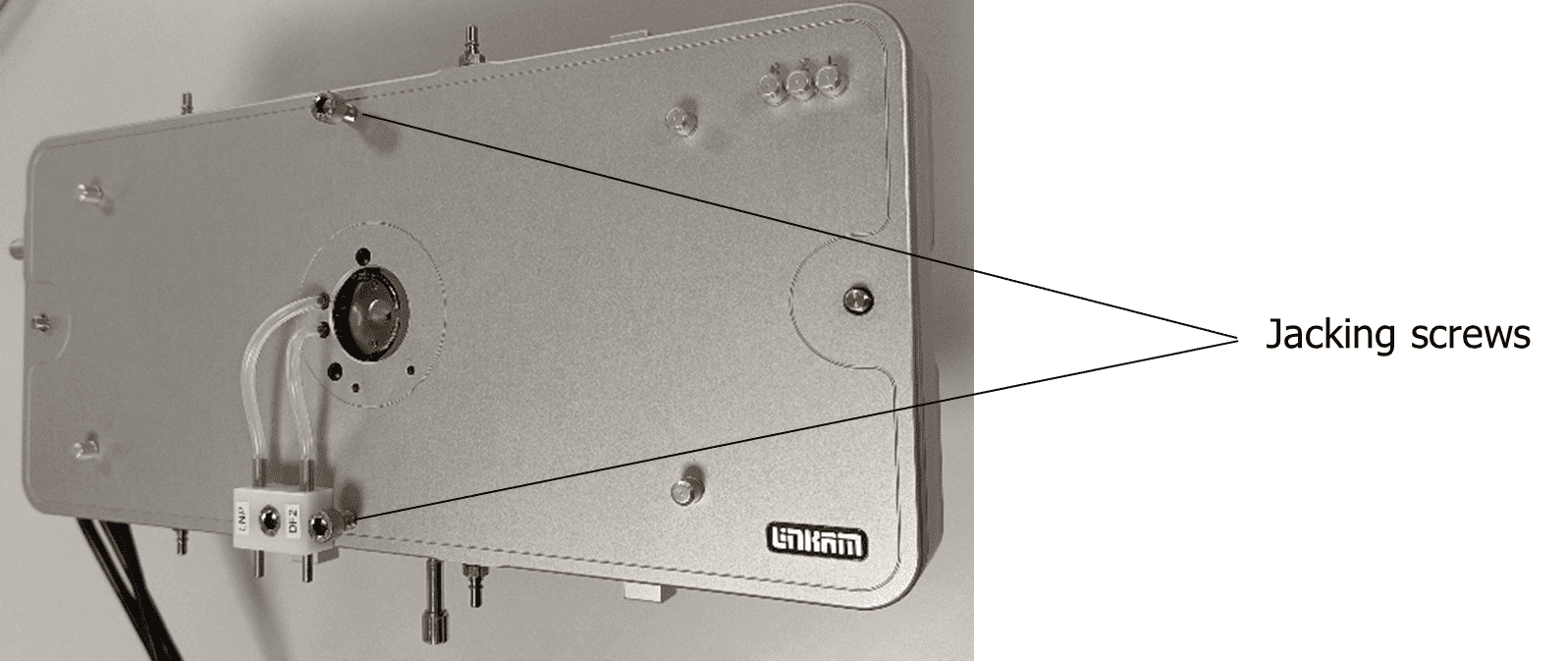

1) Place the stage on the stand and remove the two lid nuts. Install the two jacking screws into the holes in the lid as shown below.

2) Tighten the jacking screws by hand until they come to a stop.

3) Using the supplied hex key, turn one of the jacking screws a quarter of a turn and then do same to the other. Alternate with quarter turns so that the lid comes straight up. This will reduce the risk of any damage to the gap mechanism.

4) Remove the base and lid windows as detailed in the user guide. Clean the area around the two windows before replacing them. If the windows have been replaced, make sure that the R, Z and L sensors are reset as detailed in the user guide.

Do not use compressed air to clean the instrument as this may blow small fragments of glass into the various mechanisms.

Motor does not start

The shear motor will not start if the lid is off, or the temperature is open circuit. Ensure the sensor rods on the lid are seated in their respective holes in the body and the connecting cable has been attached. It may have trouble starting if the speed selected in the jog window is in excess of 7.5rad/s. This can be overcome by gradually increasing the speed from a lower velocity of approximately 4.0rad/s up to the desired level by clicking the scroll bars.

The motor may not start if the data in the shear motor profile results in a high shear rate. In this case, decrease the value in the shear rate cell.

Lid rocks slightly when the lid nuts are off

It is quite normal for there to be a slight apparent rocking of the lid when the gap is zero and the lid nuts are off. This is because the windows are touching and the absence of pressure from the lid nuts allows the lid to lift a little. However, if the gap is larger than zero, there should be no rocking. If this is the case, please contact Linkam Technical Support.

Temperature appears to be several degrees below the displayed temperature

Once the heaters have reached their programmed temperature, it will normally take a minute or so for the heat to spread evenly throughout the sample. If the sample is not in a liquid state, it may not conduct heat as efficiently as a liquid. However, should the user feel that the heaters are not accurate, there are procedures to verify them and check that their mountings have not been disturbed. Please contact Linkam Technical Support. should this occur.

Cooling Fault Diagnosis

Ensure that all connections to the stage and Dewar are as shown in the User Guide user guide.

The cooling rate is less than specified

There can be several causes of this problem, the most likely being that one of the connectors has become blocked or damaged. Check that each tube is fitted tightly to the connector and that none of the tubing is twisted. This is particularly important for the tubes connecting to the stage, as any constrictions of either the tubing or the connector will have a significant effect on the cooling ability of the LNP9X. If the connectors and tubing are OK, check that the black capillary tubing to the Dewar flask is not bent or damaged and that the brass filter from the black capillary tubing inside the Dewar is intact and unblocked. If any damage has occurred to any of these items, it will be necessary to replace them. Check that there is sufficient liquid nitrogen in the Dewar so that the brass filter is beneath the surface. If the filter is lifted above the surface of the liquid nitrogen water vapour may freeze in the filter and block it. Thaw the filter to melt the ice and dry it before reinserting into the Dewar. If the cooling problems persist, please contact Linkam Technical Support.