Materials and Metallurgy Applications

Understanding the micro and thermo mechanical properties of materials is increasingly important. Existing materials are being deployed in new environments and exotic new materials are being developed to meet ever increasing demands.

Materials such as carbon fibre and graphene are becoming established materials for applications such as bike frames, cars, surgical implants and even aircraft wings. New materials are also being developed to replace or support human body parts such as artificial hips and corneas. It is essential that the physical properties of these materials are well characterised and any failure modes well understood.

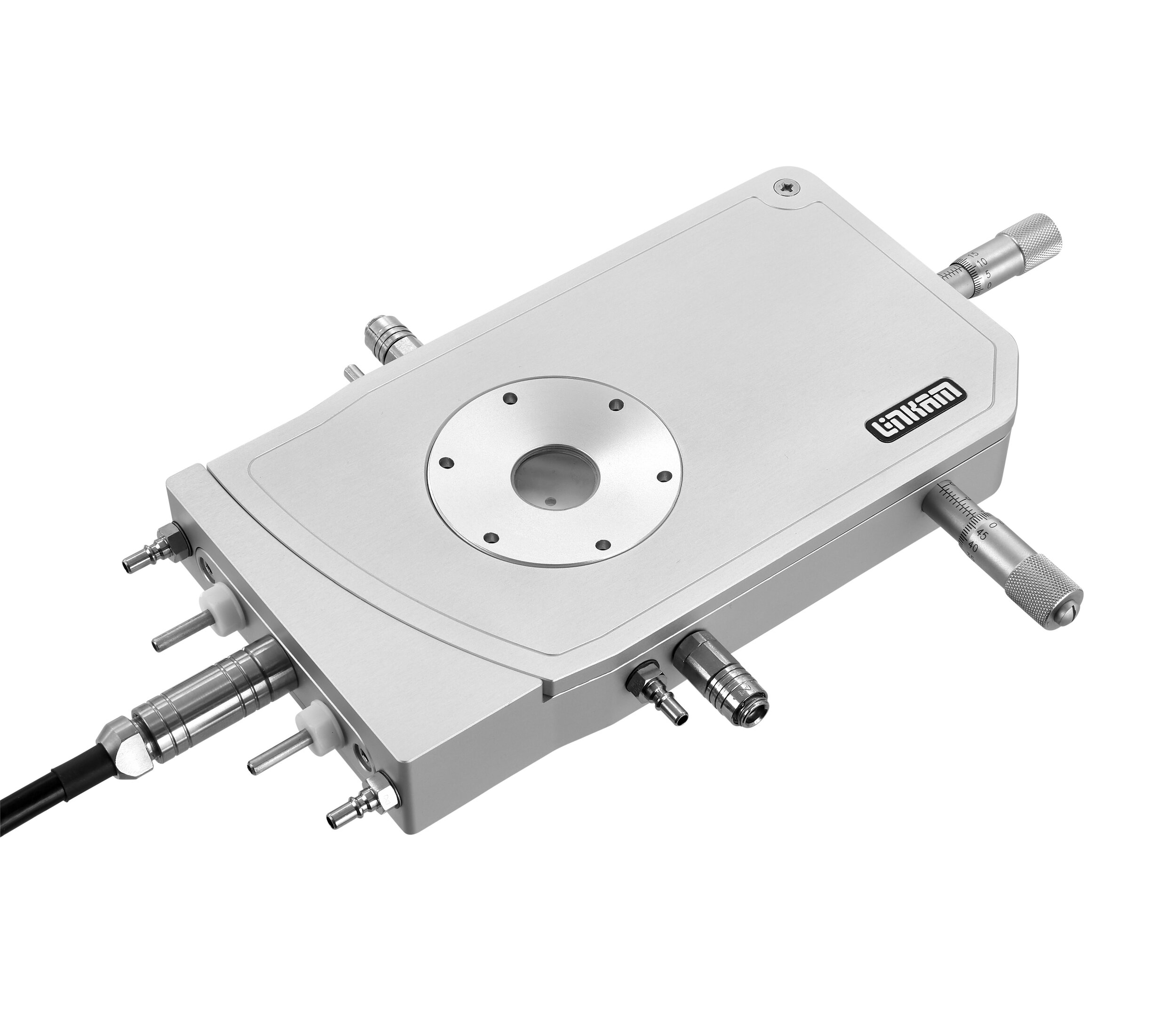

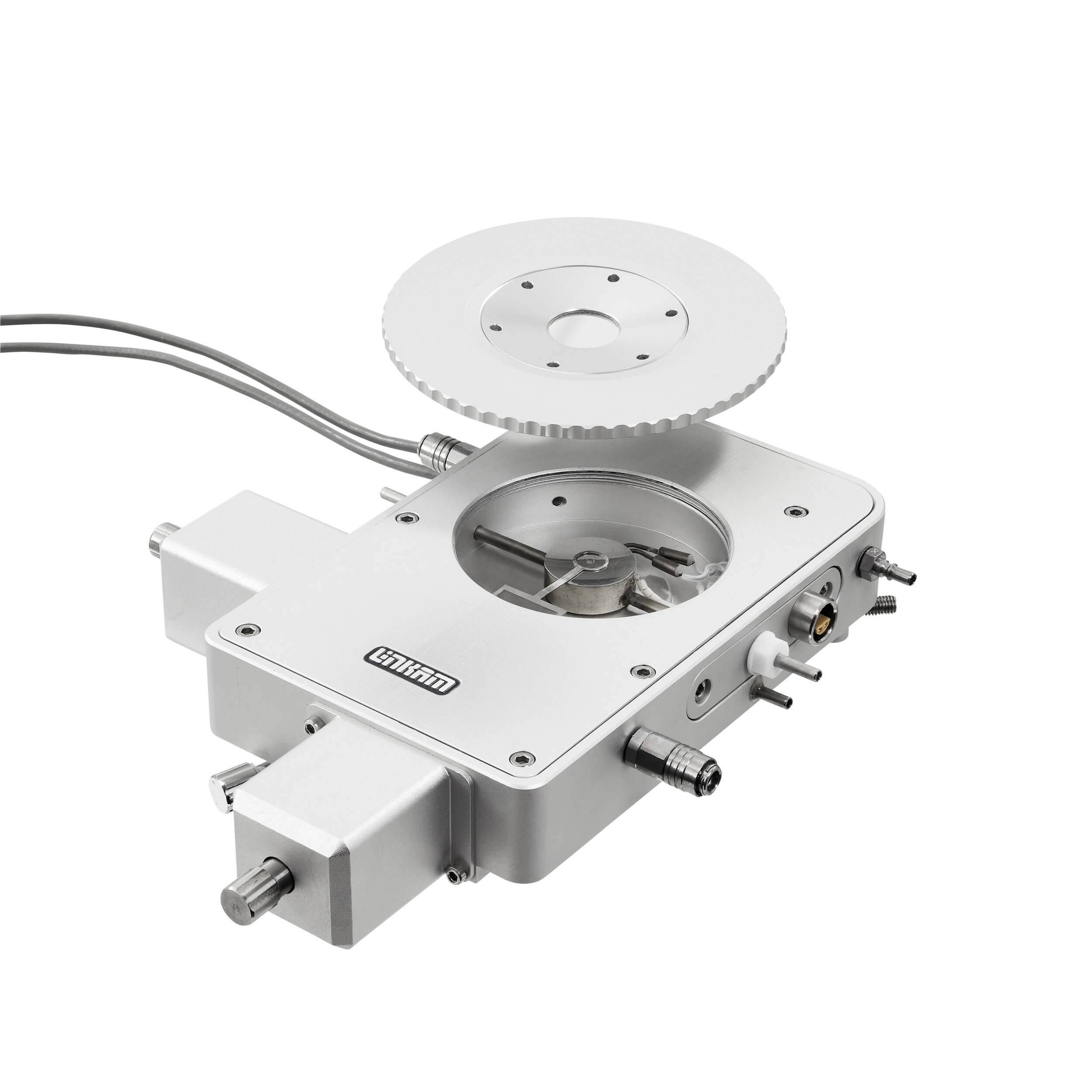

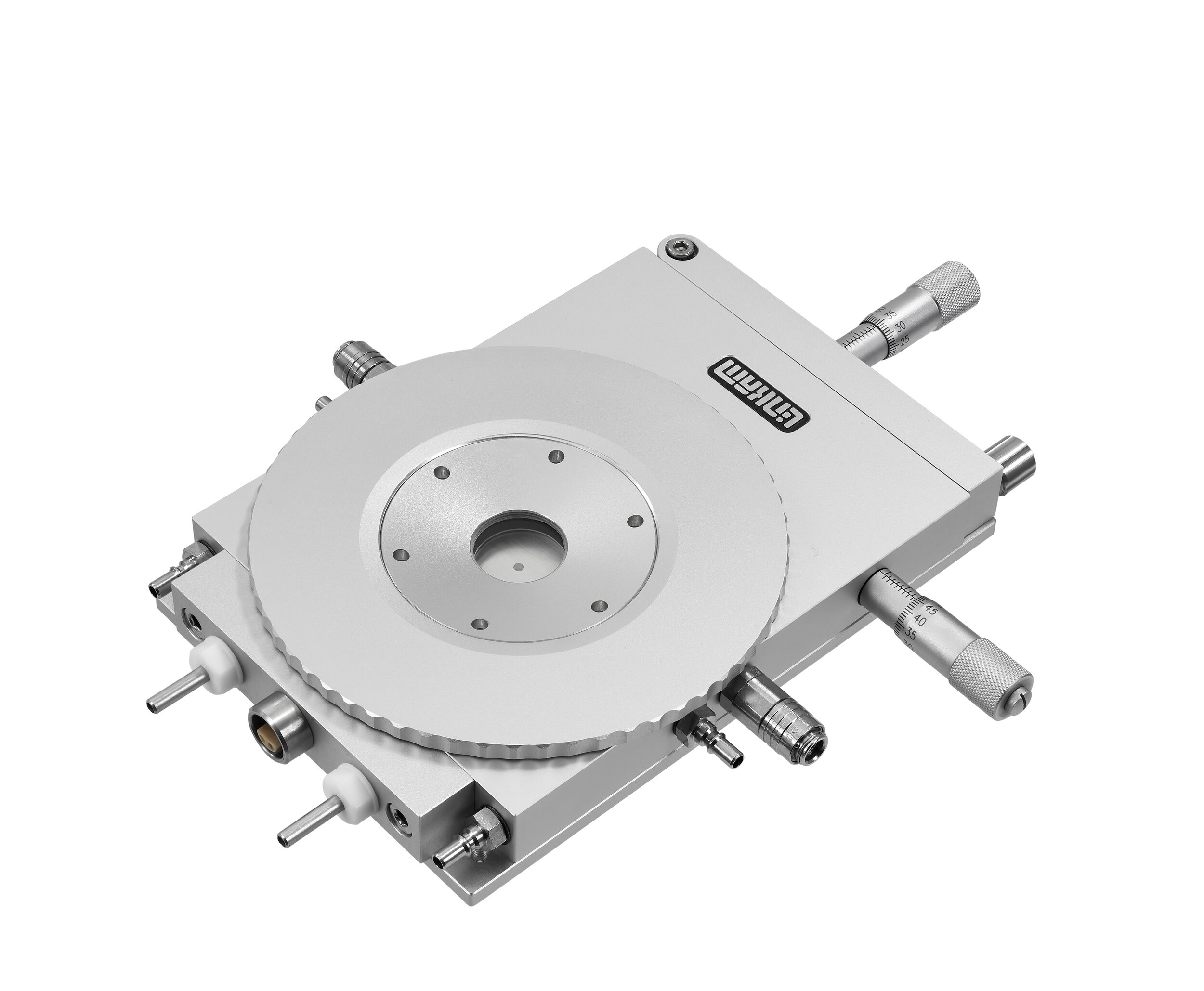

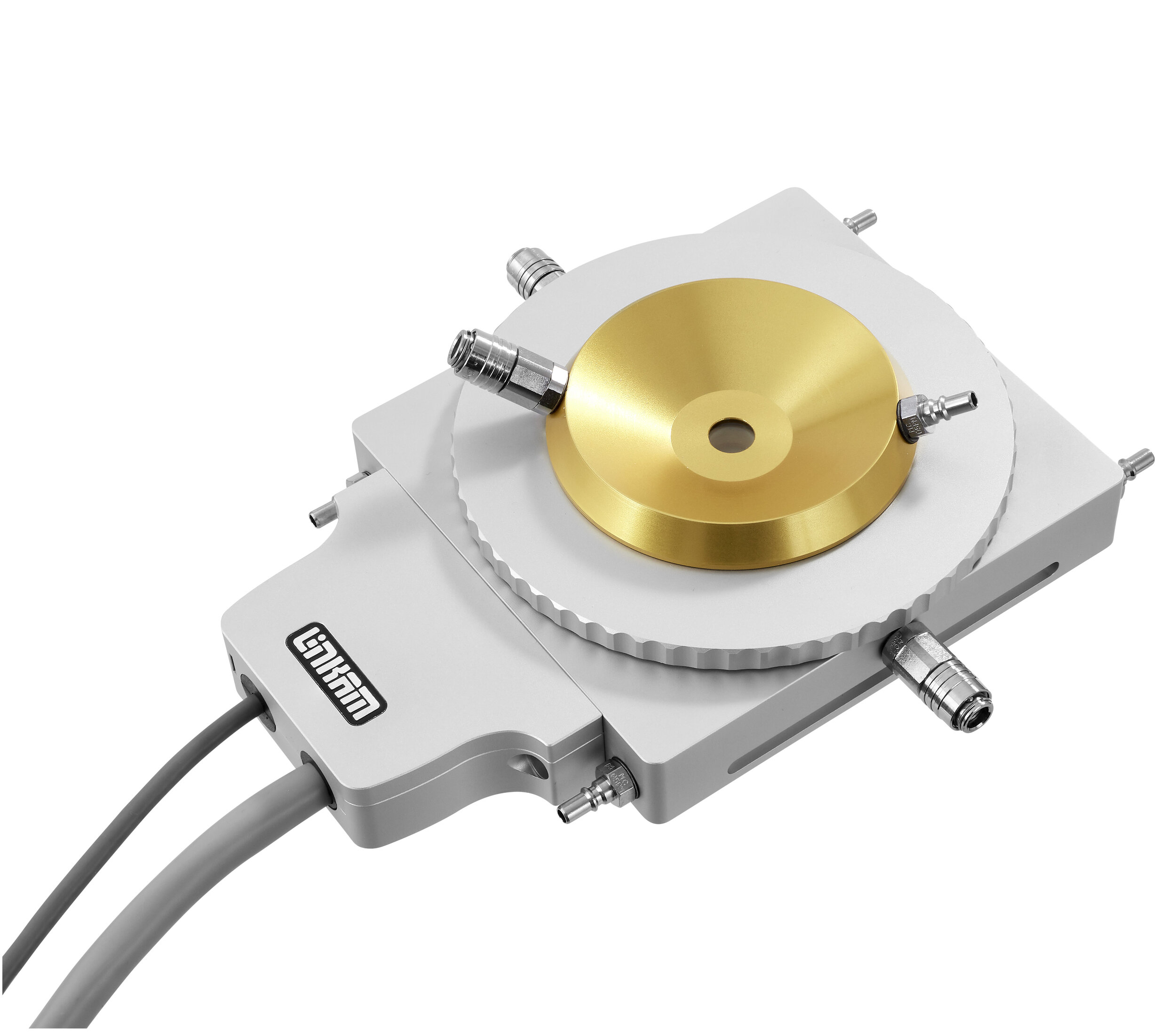

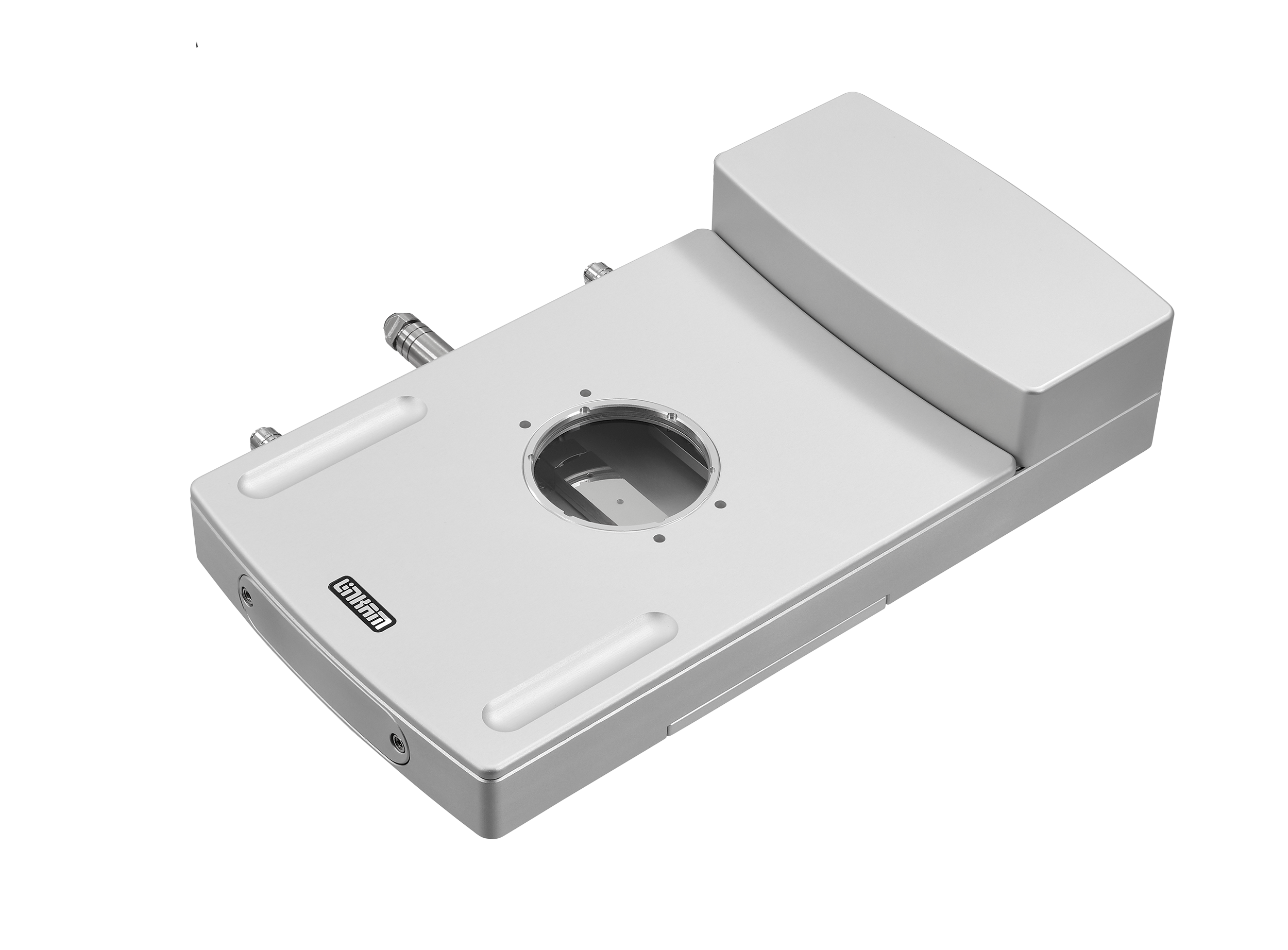

Our stages can control temperature ranges from < -195°C up to 1500°C. The environment within the chamber can also be controlled with the option of gas purging, controlled vacuum, pressure or humidity.

Linkam systems are compatible with light microscopy and spectroscopy techniques including Raman, FT-IR and X-ray.

Related Products

Published Papers

Application NOTES

The remarkable functional properties of spider silk make it a highly interesting material for a wide range of applications, including high-performance fabrics and regenerative medicine.

The understanding of microscopic and thermo-mechanical properties is at the core of materials science research. Here we look at how mechanical characterisation can be used to observe and image materials at the microscale.

This article looks at how researchers use temperature-controlled procedures with Linkam’s TS1500 to synthesize and characterize porous maghemite nanoparticles.

Researchers at the R&D division of world-leading catalyst and technology company, Haldor Topsǿe, use the Linkam CCR1000 to identify, under reaction conditions, which specific sites in their catalysts are responsible for the catalytic activity.

Researchers at the University of South Carolina studied the thermal dehydration and vibrational spectra of hydrated Lithium borohydride (LiBH₄ x H₂O) using the CCR 1000 with X-ray diffraction and Raman spectroscopy.

Read how the THMS600 is used in the analysis of glass sample in the Tulsa Forensics Department.

A study of soldering and brazing using both THMS600 and TS1500 stages to mimic industrial processes.

Researchers at the University of Bath develop understanding of novel materials with single-walled carbon nanotubes using Linkam’s tensile stages.

Researchers use Linkam’s TST350 (now replaced by the updated MFS) to study biomaterials for corneal replacement.